Reverse Logistics in the United States

To ensure the operation of the complex, it was necessary to perform the following tasks: to accept and sort small-piece goods of a large range of dimensions (up to 800 x 400 x 300mm) and weight (up to 20 kg) in various types of packaging. The commodity circulation capacity amounted to dozens of thousands of orders per day.

Customer

- The United States,

Arkansas

Timeline

2017 (6-Month Period)

Technical Solutions

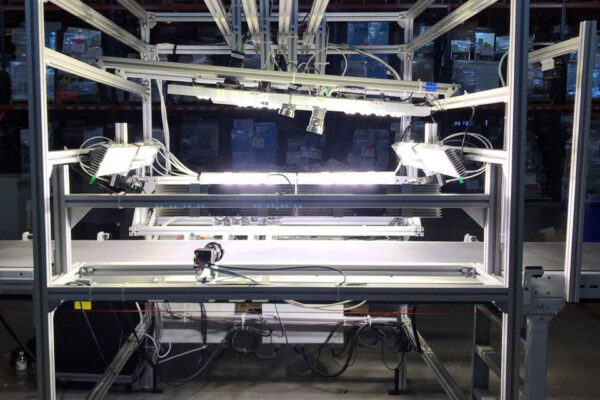

- Developed a customized sorter and conveyor systems for in-house operations

Software

- Conveyor Control System (CCS) — in-house developed software adapted and configured to meet the client’s needs.

Finalized and Completed:

- Supplied and streamlined turnkey automation equipment

- Designed and developed top-of-the-line sorting equipment for client’s sorting center

- A common management system was implemented for the entire equipment complex

- Integrated our automation technology our into client’s existing WMS system

- Professional installation and commissioning services provided

- Comprehensive service and maintenance have been provided to keep equipment running at peak performance

Custom Solutions

Our specialists have developed a scanning system and software that allows you to automatically read all the barcodes available on the product. The solution allowed scanning even small and dense barcodes with a density of 8 mil, reading codes from all sides (except the bottom) in an arbitrary orientation, as well as recognizing codes on products of arbitrary dimensions (from 50 x 10 x 10 mm to 600 x 400 x 300 mm).

Together We Can Do More

Do you have questions?

Contact us to get advice from our specialists: