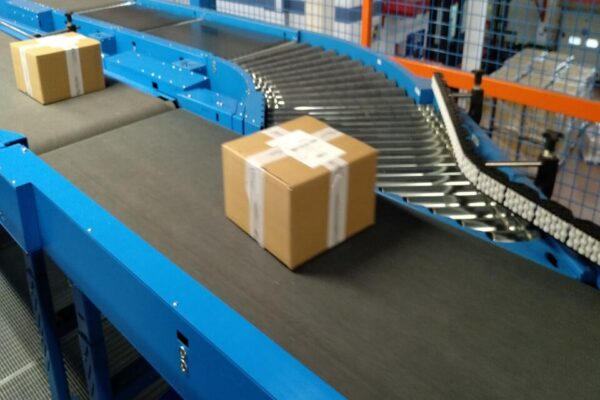

Custom Conveyor and Sorter Systems designed for multilevel floors and mezzanine layouts

Since 2018, We have continued our fruitful partnership with our client, where we first installed a sorter system, and are proud to have launched a new conveyor layout that currently allows staff to retrieve and assemble beauty products that were ordered online.

The complex is designed to handle all aspects of high-volume product orders. From measuring dimensions, packing, measuring, weighing with subsequent sorting by transportation directions –while automating invoicing for each pallet. This has enabled FM Logistic to process and fulfill thousands of beauty product to orders with ease.

Customer

- FM Logisitic

Timeline

2019

Technical Solutions

- Customized sorter and conveyor systems for in-house operations

Software

- Conveyor Control System (CCS) — in-house developed software adapted and configured to meet the client’s needs.

Finalized and Completed:

- Supply of turnkey automation equipment

- Development and production of conveyor equipment for the sorting center

- Implementation of a common management system for the entire equipment complex

- Integration with WMS

- Installation and commissioning

- Service maintenance

Custom Solutions

Photomechanics’ specialists have developed an innovative solution that is designed to streamline the sorting process and increase productivity. By creating semi-automatic secondary sorting columns, we were able to assign up to three virtual goals of sorting by giving directions to one sorter target. This unique solution saves space, simplifies the sorting process, and ensures that our client can meet his productivity targets without compromising on efficiency.

Together We Can Do More

Do you have any questions?

Contact us to get advice from our specialists: